Table of contents

When the COVID-19 pandemic started to seriously disrupt supply chains, the United States Food and Drug Administration (FDA) immediately issued guidance and asked for earlier notification of manufacturing and supply chain issues. In the guidance, the FDA asked for “timely, informative notifications” about manufacturing disruptions to assist in “efforts to prevent or mitigate shortages of products.”

Enabling all employees and supply chain partners to report incidents as soon as they are identified, and then notifying the proper team members, kickstarts the resolution process and reduces risk simply by closing issues faster.

As demonstrated by the FDA’s request, a simple way to reduce the impact of supply chain disruptions is to start resolving them faster through early notification. Supply chain leaders must ask themselves if they have properly enabled their internal teams and supply chain partners with the required tools to quickly notify the right people about supply chain issues.

How to create earlier notifications of supply chain issues

Most companies lack systems or operate inadequate systems for tracking supply chain issues across internal functions and out through external supply chain partners on an end-to-end basis. Without adequate systems in place, neither employees nor supply chain partners are able to inform the company of supply chain issues in a timely and informative manner. The lack of a Supply Chain Work Management (now POET) system leads to late and slow resolution processes that limit the corrective actions that could mitigate the downstream impact of the issues.

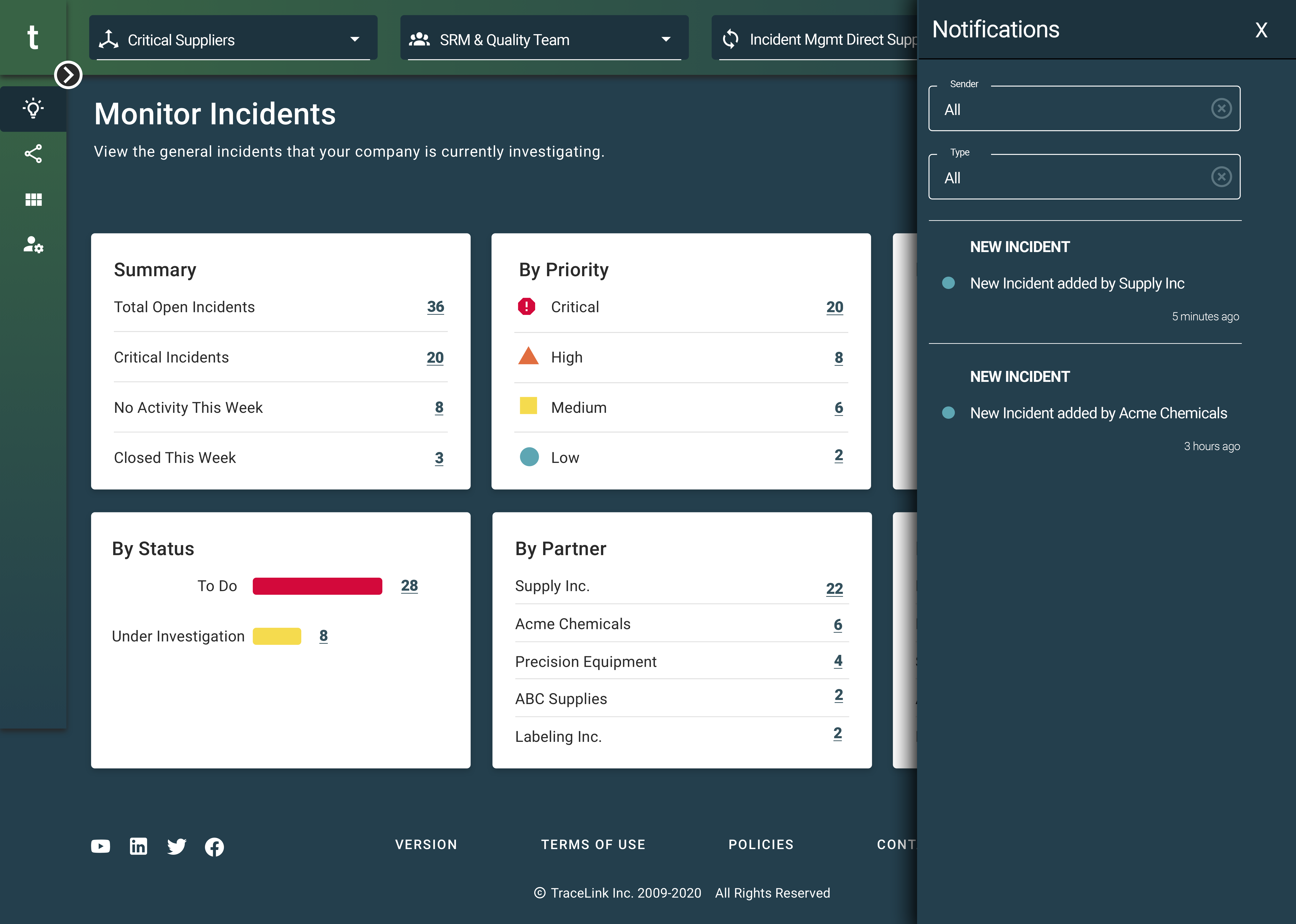

With Incident Management, a process of TraceLink Supply Chain Work Management (now POET), companies can equip their internal teams and supply chain partners with a structured solution to report issues accurately with the click of a button. A simple description is enough to inform the right team members about a critical issue. For a more complete description of the issue, easy-to-use drop-down lists guide the user through the most important information associated with the issue. Companies can customize their own data fields and workflows to match their unique issue management requirements using OPUS Solution Designer, a low-code/no-code solution that enables business analysts to quickly configure and customize experiences for efficient issue management.

Supply Chain Work Management (now POET) brings speed, structure, visibility, and greater operating efficiency to issue management processes. After the issue has been added, the right team members in the right departments are notified of the open issue.

For example, a manufacturer can add a material shortage issue, provide all of the details of the issue, and assign the issue to the right person in customer service at the supplier responsible for the shortage. The customer service representative at the supplier will be notified of the issue immediately and begin working on the resolution in a way that is transparent to all team members involved. Relevant team members can collaborate and follow the issue, receiving notifications as the issue is updated. The manufacturer and supplier will document their progress and collaborate in Supply Chain Work Management (now POET) until the issue is resolved.

Enabling all employees and supply chain partners to report incidents as soon as they are identified, and then notifying the proper team members, kickstarts the resolution process and reduces risk simply by closing issues faster. Supply chain leaders who have enabled earlier notification of supply chain issues with Supply Chain Work Management (now POET) have achieved up to 65% faster resolution time of issues across their organization as well as reduced overall incidents by as much as 35%, among other incredible performance improvements.

Just as the FDA asked for early reporting of issues to mitigate supply chain disruptions caused by the pandemic, supply chain leaders should be enabling their internal and external teams with digitalized Incident Management processes. Reducing risk in the supply chain starts with knowing about threats as soon as they occur.

Learn more in our Supply Chain Work Management (now POET) Resource Center.