Table of contents

While many large pharmaceutical companies have the staff and resources required for serialization planning, smaller and virtual manufacturers in the EU are already falling behind. With just two years until the EU Falsified Medicines Directive (EU FMD) compliance deadline, businesses in Spain are turning to traceability experts to help them prepare across all levels of serialization.

One such organization is Altran, a company with decades of experience helping supply chain companies in Spain and throughout the EU. In a recent conversation with Altran Solution Architect José Guijarro Peralbo, we discussed the pharma landscape in Spain, and the technical challenges of EU FMD that companies must overcome in the coming months.

Altran has been known as a global leader in engineering services for over 30 years—what’s your company’s experience in life sciences?

We’ve been delivering operational excellence and system integration expertise for life sciences in Spain for more than 15 years. We help improve performance in packaging lines, production lines, and we provide customer support to optimize processes and operations. Once the processes are optimized, we work with automation and IT teams, developing process controls, PLC, SCADA, and DCS, and other systems like Historian and MES-EBR. We act as a system integrator to collect data from the equipment, and from others systems, such as the quality management system (QMS) and laboratory information management system (LIMS), and we integrate that data into other systems like electronic batch record (EBR), Historian, or enterprise resource planning (ERP) systems.

Additionally, two years ago, Altran began serving pharma companies in overcoming the serialization challenge by providing consulting, integration, project management, and operations support services.

What is the landscape of the pharmaceutical industry in Spain?

Spain has more than 100 small and medium pharma companies. What we have most are CMOs that work with pharmaceutical companies that aren’t manufacturers. Most of them export outside of Spain. On average, 60 percent export outside of the European Union, and many of them export at least one product to the United States.

What are the biggest challenges that pharma companies are facing in Spain today?

The medium and small companies are growing fast because the market is growing. Their biggest challenge in Spain right now is to grow as fast as they can, while at the same time complying with all the quality requirements.

Most of our customers are really busy because they have older projects in their portfolio that take priority, and they have to buy new lines and new facilities to grow. At the same time, they have to maintain compliance. That's the big challenge. They don't have enough expertise, knowledge, and staff, and they are not ready to grow so fast.

In most cases, they don’t understand the quantity of work that serialization means for them. They are so busy and have so many projects in their heads that they don't want to analyze serialization.

How prepared are companies for serialization across all 5 levels?

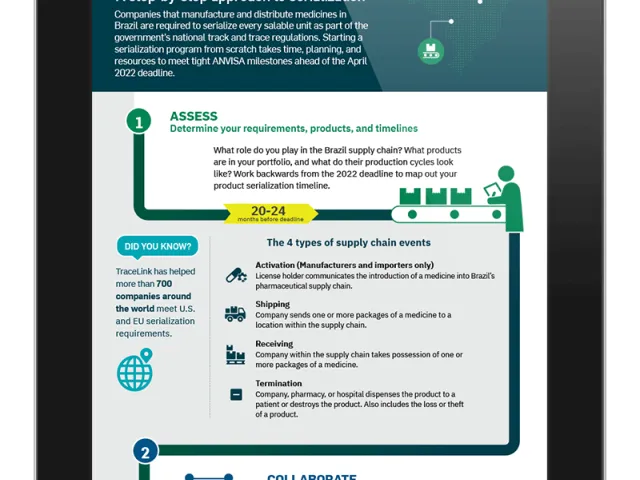

There are a few companies who haven't started anything yet—they are still waiting or asking for funding for the serialization project. The most common scenario is companies that have bought just one or two pieces of equipment, such as a leveler with a camera and printer. They are starting to test something with a pilot project, but only for level 1 and level 2—they don't have software on their third, fourth, and fifth levels. The next step for them is to find a suitable solution to cover level 3 to level 5.

What’s the current status of Spain’s national system?

The national repository system for Spain is still under development. There is a lack of information right now about the project and all the requirements to connect the distribution centers, the pharmacies, and the hospitals.

When do companies in Spain need to connect to the European hub for compliance reporting?

They should connect before the February 2019 deadline. We have been in contact with the European Medicines Verification Organization (EMVO), and they are going to publish all the requirements for connecting to the European hub. We can provide the support to our customers to start the process of establishing the connection.

What challenges specific to CMOs are you seeing?

For CMOs working with at least 20 customers, the challenge is that very few customers have specific requirements for serialization right now. The CMOs are a bit confused in communicating with their customers, because their customers are not able to define their final requirements yet.

Because serialization is such a large endeavor, how can exceptions processing impact a company’s serialization solution?

Serialization is a huge project with a huge impact in the organization, so you need to prepare for all the exceptions before implementing serialization—it's very important to not underestimate this work.

In the production area, for example, there can be an exception if a particular product reference doesn’t have folding boxes or they are not printing on the labels. For instance, we had the experience of preparing one line for serialization, and everything was more or less fine. However, we incurred an exception when a specific reference was sent to the market without a carton. The production was blocked because the system wasn't ready for this situation.

Another lesson learned is not to underestimate the number of procedures you’ll need to modify, update, or create. If you don't have all the procedures updated, you are not able to serialize.

We have learned that the performance of the lines—the overall equipment effectiveness (OEE)—potentially goes down. With serialization implementation, OEE goes down about 3-5%, and with aggregation and serialization, it goes down 10-15%. With our experience, we can take some action on levels 1 and 2 that will minimize the impact of serialization on the performance in the lines.

Once the regulations are in place, what will happen if companies can’t serialize product?

Their business will stop and they won’t be able to ship product.

How will the partnership between Altran and TraceLink help customers achieve EU FMD compliance?

Altran and TraceLink provide confidence to our customers so they know they will be ready for compliance with the European law. There isn’t time for customers to make the wrong decision when selecting a vendor. Altran and TraceLink share the vision that serialization is not only a technology challenge, but a global business operations and technology challenge for pharma companies. By working together, we leverage our knowhow on operations impact, technology integration, and regulatory compliance, and we solve any language barrier, or local culture specifics. Our customers understand that TraceLink provides a flexible and best-in-class solution for level 4 and level 5, and the key for local integration services support comes from Altran.