Table of contents

Key Takeaways

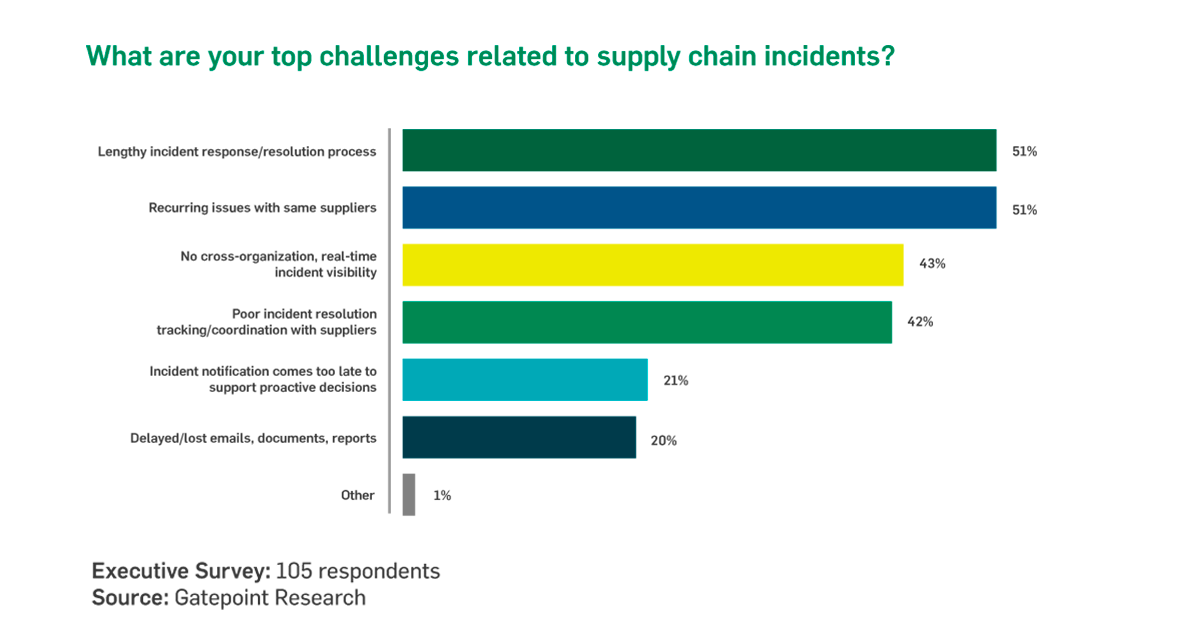

- Lengthy incident response times and managing recurring issues are the two biggest supply chain issue management challenges facing manufacturers today.

- Collaborative, multienterprise applications can help manufacturers overcome the top six obstacles to issue management success.

Supply chain incident resolution processes that take too long and managing supply chain partners that cause recurring problems are the top challenges manufacturing organizations face when addressing supply chain issues like late shipments, material shortages, and quality defects, according to a recent survey conducted by Gatepoint Research on behalf of TraceLink.

The survey of 105 manufacturing company leaders—including managers, directors, vice presidents, and C-level executives—found that a lack of real-time visibility that crosses company boundaries; poor coordination and communication with supply chain partners; delays in reporting issues; and unstructured collaboration tools like emails and documents round out the top six challenges to effective supply chain issue management.

A smarter way to manage and resolve supply chain issues

While challenges like lengthy issue resolution times and problematic supply chain partners continue to plague many manufacturers, the news is not all bad, according to supply chain luminaries from multiple industries who spoke at the recent Future Insights Digital Supply Network Strategy Day event.

The event speakers explained that new technologies like cloud-based digital supply chain network creation platforms and collaborative, multienterprise supply chain applications are helping manufacturers speed up issue resolution time, reduce repeat deviations, and improve delivery performance.

It's just the tip of the iceberg as we start to digitalize every single aspect of the supply chain, and start to then merge that with the capabilities of technology to take it to levels of performance that were only dreams 10 years ago.

Steve Hydzik, a longtime Vice President and Global Head of Manufacturing and Supply Chain at The Merck Group KGaA, said the top challenges manufacturers face stem from the fact that supply chains have grown significantly larger and more complex.

“As we continue to drive more and more externally, the challenge is how do we gain visibility?” Hydzik said during a Future Insights session with TraceLink CEO Shabbir Dahod. “How do you gain access to information? How do you gain visibility to execute the supply chain? How do we get products to be released on time? How do we ensure that we're addressing defects or deviations in a timely manner?”

Hydzik explained that the answers lie in using new digital technologies to tighten supply chain collaboration and support continuous business process improvement methodologies.

“It's just the tip of the iceberg as we start to digitalize every single aspect of the supply chain, and start to then merge that with the capabilities of technology to take it to levels of performance that were only dreams 10 years ago,” he said. “The use of technologies to keep every node of the supply chain informed of what is happening to drive excellence is a tremendous opportunity out there.”