Table of contents

In the face of widespread and increasingly frequent disruptions, pharmaceutical industry leaders are under pressure to measurably improve visibility and collaboration across the supply chain. The goal is to increase supply chain agility and share insights with trading partners in real-time to ultimately drive better decision making—which translates into increased customer service levels, profitability, and better patient outcomes.

Unfortunately, the level of interoperable information exchange between supply chain partners required to support real-time, end-to-end visibility and collaboration is out of reach for most companies because of time, cost, and technical limitations associated with integrating to hundreds or even thousands of trading partners. As a result, pharmaceutical manufacturers are left searching for innovative ways to engage supply chain partners and improve visibility and collaboration with the goal of mitigating disruptions and optimizing key metrics such as on-time, in-full.

As Gartner* noted in a recent research report, “Despite increasing disruptions, many organizations still lack the capabilities to have a more holistic, end-to-end (E2E) view of what is happening to and in their supply chains. This includes views upstream to an organization’s suppliers and contract manufacturers, as well as downstream with its logistics and delivery providers.”

While the Gartner research is based on all manufacturing industries, it does show that the challenges of end-to-end supply chain visibility and collaboration are pervasive and not limited to the pharmaceutical industry. Gartner believes the answer lies in what it has defined as multienterprise collaboration networks (MCNs). Noting that Gartner considers TraceLink an MCN, they define “MCNs as solutions that support a community of trading partners of any tier and type that need to coordinate and execute on business processes extending across multiple enterprises.”

TraceLink Recognized the Need for a Multienterprise Collaboration Network 15+ Years Ago

End-to-end visibility and collaboration across the trading partners of the pharmaceutical supply chain is paramount to patient safety. That is why TraceLink built its industry-leading track-and-trace solutions on a network to ensure that organizations can understand the full pedigree of a product—and verify its legitimacy—with a simple scan from anywhere in the world. A key to the success of the TraceLink network, which now has 290,000+ member organizations, was to make it possible to rapidly and cost-effectively onboard trade partners of any size and any level of digital maturity—from a global pharmaceutical manufacturer to a local clinic.

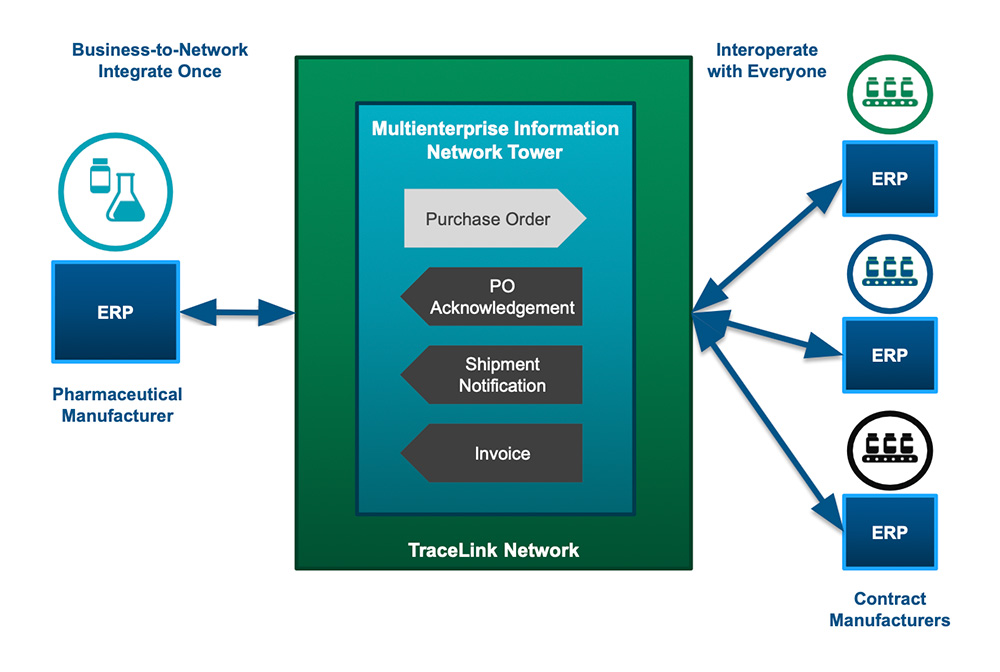

With the introduction of the new Multienterprise Information Network Tower (MINT), TraceLink is increasing the scope of network capabilities. The TraceLink Business-to-Network Integrate-Once model enables companies to exchange interoperable business transactions and “coordinate and execute on business processes across multiple enterprises.”

MINT: The Network Solution for End-to-End Visibility and Collaboration

MINT leverages the proven capabilities of the TraceLink network and the Opus platform to enable trading partners to seamlessly exchange supply chain business information, including commerce, inventory, and logistics transactions, in the cloud with 100% interoperability. TraceLink leverages lessons learned from creating a 290,000+ entity track-and-trace network that members use to exchange data on billions of serialized products each year across the end-to-end pharma supply chain. Key performance metrics include:

- 7,400+ CMO connections

- 50, 000+ ASNs per month

- $4.7 billion+ saved by eliminating point-to-point (P2P) integrations

While a new solution, MINT is an expansion of the current interoperable transaction exchange of serialized data, aggregations, advanced shipping notices, and other transactions that the pharmaceutical industry has been using for 10+ years.

The Answer to Supply Chain Visibility and Collaboration Is Here!

MINT is 10-100 times faster to implement and less expensive than current data exchange methods, including EDI or P2P integrations, giving pharmaceutical manufacturers and their supply chain partners a feasible way to digitally exchange business transactions. With cost-effective and efficient integration, pharmaceutical manufacturers can finally gain real-time end-to-end supply chain visibility and collaboration to create a truly agile supply chain with their trading partners using a “win-win” deployment model.

Initially, MINT enables the network exchange of purchase orders, invoices, inventory status, forecasts, chargebacks, and much more with all supply chain partners. Real-time interoperable exchange of purchase orders alone greatly improves visibility to demand changes and helps supply chain partners focus on collaboration that creates a more agile and resilient supply chain. As supply chain partners exchange more business transactions such as forecasts, inventory status, production status, and shipment notices, visibility and collaboration will improve even further and have a meaningful impact on the uninterrupted flow of medicines to patients.

For information or to be considered for the MINT Customer Launch Program, contact Amanda Bettman, General Manager for Supply Network Orchestration, at abettman [at] tracelink.com (abettman[at]tracelink[dot]com).

*Market Guide for Multienterprise Collaboration Networks, Christian Titze and Brock Johns, Gartner, April 18, 2023