Table of contents

Pharmaceutical companies are increasingly cutting costs and gaining access to specialized capabilities by outsourcing drug production to external manufacturers, but those benefits have come with a cost: a reduction in control over manufacturing processes. Now external manufacturing and supply chain leaders are seeking to improve visibility to drive proactive collaboration with contract manufacturing organizations (CMOs).

Pharmaceutical companies are increasingly cutting costs and gaining access to specialized capabilities by outsourcing drug production to external manufacturers, but those benefits have come with a cost: a reduction in control over manufacturing processes. Now external manufacturing and supply chain leaders are seeking to improve visibility to drive proactive collaboration with contract manufacturing organizations (CMOs).

The need to reduce costs and access specialized production capabilities—which are especially important in biopharma—is driving steady growth in the pharmaceutical contract manufacturing market. The market is expected to grow by 6% annually from $119.3 billion in 2022 to $179.4 billion by 2030, according to Market Research Future, a global market research company.

But a lack of real-time collaboration with CMOs and reduced visibility into manufacturing processes often leads to problems such as late orders, product shortages, higher inventory levels, lower on-time customer delivery performance, and missed revenue.

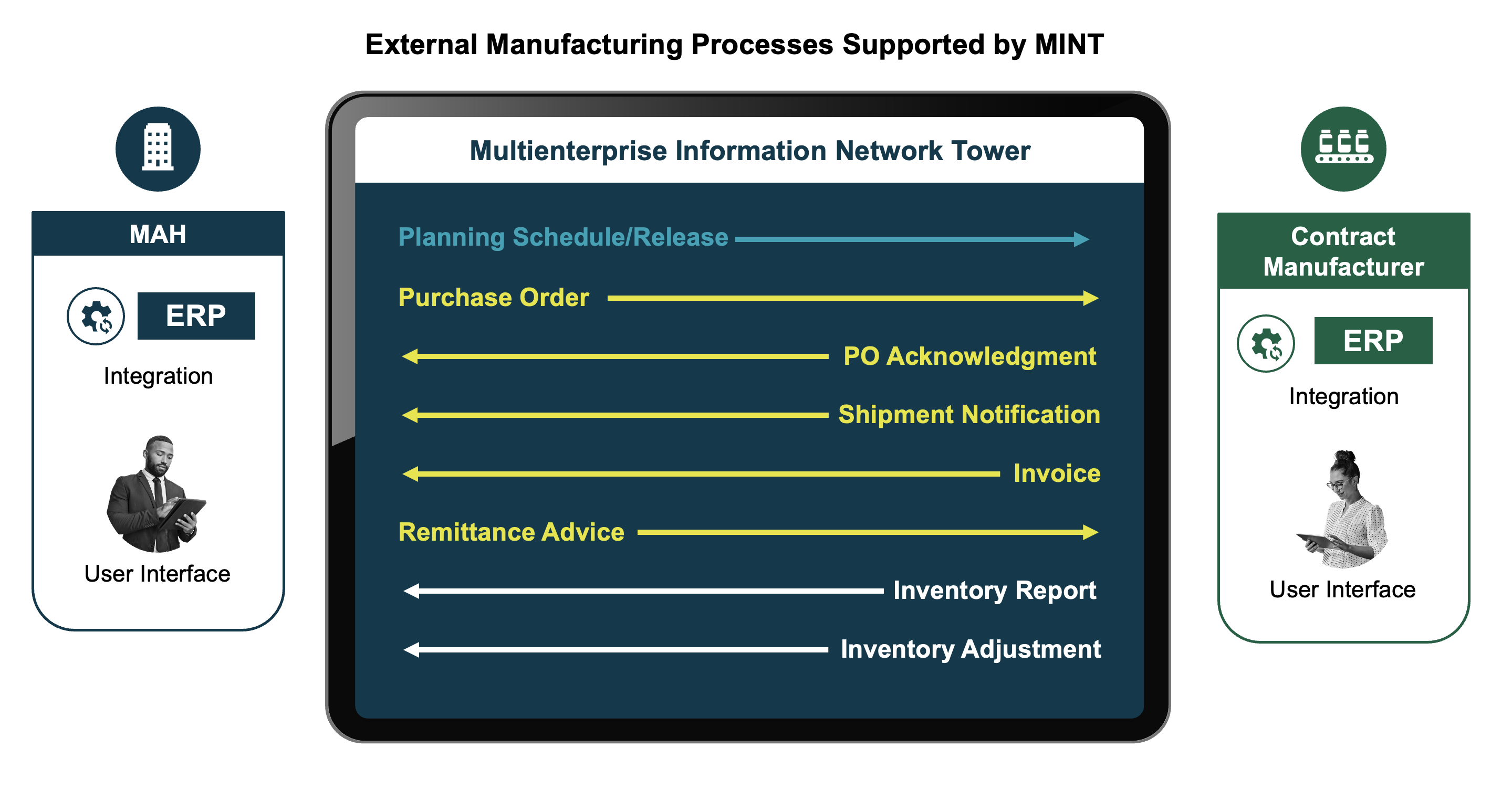

The good news is that external manufacturing and supply chain leaders at pharmaceutical companies can significantly reduce or eliminate these issues, boost visibility, increase collaboration, and exercise greater control by using TraceLink Multienterprise Information Network Tower (MINT) to digitalize critical supply chain processes, including the exchange of forecasts, purchase orders, purchase order acknowledgements, shipment notices, invoices, and much more. Some of the benefits you can realize immediately with MINT include:

- Improved on-time delivery through synchronized order collaboration and production status monitoring.

- Greater agility through real-time transaction exchange, which enables pharmaceutical companies and CMOs to adjust product priorities and schedules in response to volatile demand or supply chain disruptions.

- Improved supply chain planning that is based on accurate CMO inventory data and acknowledged PO quantities and delivery dates from all suppliers.

Some of the longer-term benefits of MINT include:

- Improved planning reduces production and delivery variability, enabling shorter lead times and cycle times.

- Shorter lead times and cycle times require less buffer inventory and can reduce carrying costs by millions of dollars.

- Reduced variability, shorter lead times, and real-time information exchange enables you to reduce the size of order quantities and greatly increases supply chain agility.

End-to-end visibility and real-time collaboration with MINT

MINT uses the proven TraceLink Business-to-Network, Integrate-Once™ capability to reduce the time and cost of digitalizing information exchange and shared supply chain processes between your organization and CMOs. With MINT, the Business-to-Network, Integrate-Once™ capability ensures that organizations can exchange data with all supply chain partners with just a single integration to the TraceLink network.

MINT runs directly on the TraceLink network, the life sciences industry's largest digital supply chain network, which consists of more than 291,000 member companies. Initially designed to power global track-and-trace solutions, the TraceLink network is used by trade partners across the life sciences supply chain to exchange data on billions of serialized products each year. The network supports more than 7,400 CMO connections and the exchange of more than 50,000 advance ship notices sent each month. The overwhelming majority of pharmaceutical brand owners and CMOs are already connected to the network, ensuring that integrating with your trade partners will be fast and easy—and trade partners that are not already on the network will be onboarded by TraceLink at no additional cost.

With free partner onboarding, MINT makes it possible for pharmaceutical companies to connect with all of their customers, suppliers, and 3PLs, while enabling everyone involved to share in the benefits of improved visibility and collaboration. As a result, partners are more likely to participate and blind spots in the supply chain network are eliminated. This level of connectivity and visibility is especially important for pharmaceutical manufacturers, who are well aware that virtually any supplier can cause supply chain disruptions.

MINT supports a wide range of multienterprise business transactions and processes, including several that are critical to helping external manufacturing teams improve visibility and collaboration when working with CMOs. These include bidirectional communication of forecasts, purchase orders, PO acknowledgements, and inventory status updates, all of which are key to ensuring that both parties are aligned on order quantities, delivery dates, as well as priorities when multiple products are being produced.

Let's take a closer look at how the typical external manufacturing process works—and how this process is dramatically improved with MINT.

First, a purchase order or a release against a blanket order is generated by the enterprise resource planning (ERP) system based on forecasts, on-hand inventory, and customer orders. The purchase order is then communicated to the CMO via electronic data interchange (EDI) or email. Oftentimes, this is a one-way communication and there is little or no feedback from the CMO until the order is about to hit the production line. At this point, with time running short, there are far fewer actions that can be taken when problems arise, and the order often ends up being late or underproduced.

With MINT, purchase orders generated by ERP are sent directly into the TraceLink network where they are immediately available to your suppliers via their network connection. CMOs can choose to have the purchase order routed into their ERP system, or they can access it directly through the MINT user interface. Your CMOs will benefit because they can use this same user interface with any other partner who is connected to the TraceLink network.

With MINT, all purchase order information is available in real time to be reviewed and updated as needed. MINT also supports purchase order acknowledgements, which enables the supplier to provide real-time feedback on whether they have the capacity to deliver the quantity requested on the expected delivery dates. This immediate feedback increases the time you have to find a resolution to any issues that might be blocking the order from being delivered on time.

Contact TraceLink to learn more

What if this same type of real-time communication was the norm for all purchase orders with all suppliers? That would mean far fewer missed delivery dates resulting from missing or late APIs, packaging, or other components. With real-time monitoring of confirmed delivery dates and quantities, the external manufacturing team can address these issues before they impact customer shipments and ultimately patients. MINT is the key to improving visibility and real-time collaboration with 100% of your CMOs.

Contact TraceLink today to schedule a meeting and learn how simple, fast, and cost-effective it can be to digitalize your external manufacturing operations.