Table of contents

Key Takeaways

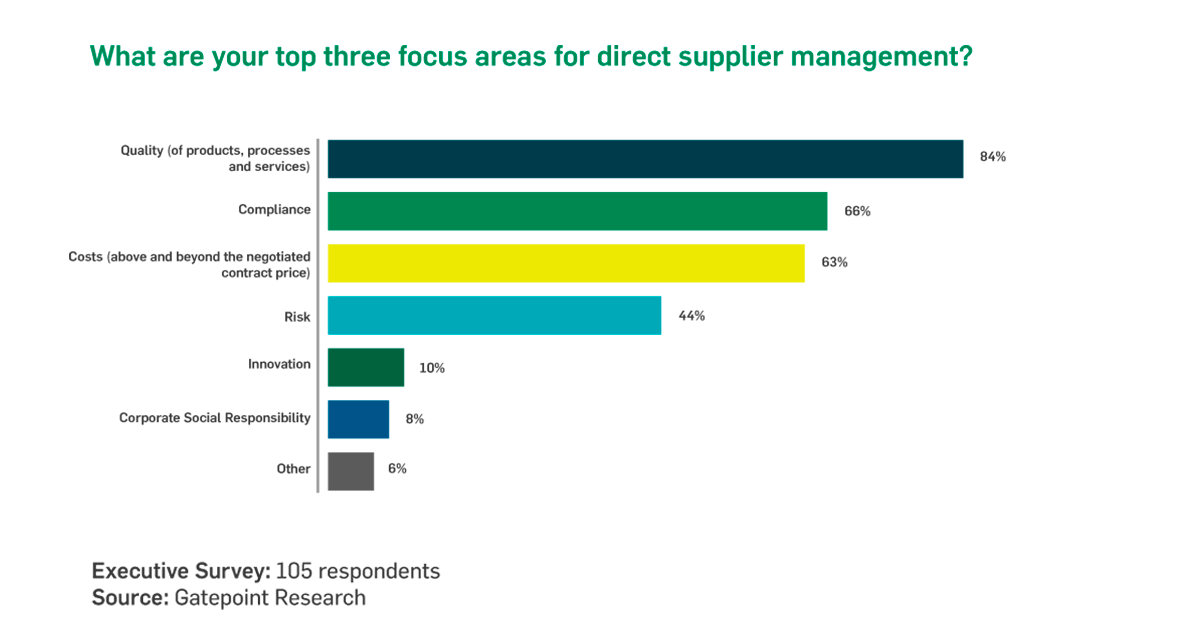

- Improving supplier quality is the top priority for 84% of supply chain executives at manufacturing companies.

- New types of digital collaboration and communication can empower improvement efforts in this area.

When it comes to direct supplier management, improving the quality of product, processes, and services is a top priority among manufacturing executives in the life sciences space, according to a new survey conducted by Gatepoint Research. However, the methods they currently use to collaborate with supply chain partners may leave opportunities for improvement.

As businesses look to reinvent the way they manage direct suppliers, one focal point of improvement stood out among the rest: quality. A whopping 84% of respondents said their top priority for direct supplier management was improving supplier quality, according to the survey.

Trailing behind, compliance (66%), costs (63%), risk (44%), innovation (10%), and corporate social responsibility (8%) were also cited as priorities. Gatepoint polled more than 100 company leaders—including managers, directors, vice presidents, and C-level executives.

Improving the quality of interactions improves the quality of the supply chain

Direct suppliers are vital strategic partners—their ability to deliver goods and services has a direct impact on a manufacturing organization’s ability to satisfy the needs of customers. Prioritizing the improvement of the systems that manage supplier quality are key to running a successful supply chain.

However, the way many businesses collaborate with their suppliers may not be ideal for driving further optimization of these systems and processes. The majority of interactions between life science companies and their supply chain partners are happening across email (with relevant information shared in attachments), phone calls, and meetings (virtual and in person), according to Gatepoint Research’s survey.

As supply chain networks grow more sophisticated and expand to include more partners, these communication avenues can pose multiple challenges. Some common obstacles include:

- Lack of visibility and transparency of all supply chain interactions from start to finish

- Difficulty ensuring the right people are involved when resolving issues

- Trouble managing communications in a timely and efficient manner

A virtual workspace designed for the realities of Industry 4.0

Digital multienterprise work management solutions can dramatically improve collaboration across the supply chain. By bringing your entire supply chain network together under one roof in a single virtual workspace, you can improve the way you interact with your strategic partners and gain complete alignment across people, processes, and technology.

Agile Process Teams for Supply Chain Issue Management (APT-SCIM) was designed specifically for this type of high-touch, fast-moving environment. With APT-SCIM, supply network teams have the power to:

- Create digital networks to link internal and external stakeholders

- Assemble internal and external digital teams across functional boundaries

- Use prebuilt solution templates to instantly communicate changes to suppliers and customers

- Customize solutions and extend workflows to build better supply chain relationships

- Use dashboards to track active incidents, change requests, and document reviews

Collaboration across the supply chain has never been more important. Make sure your organization is equipped to thrive in today’s era of sophisticated supply chain networks that rely on tight coordination between a multitude of different organizations and partners with APT-SCIM.

Download our new handbook to learn more about the power of multienterprise work management apps like APT-SCIM.